One in six people is expected to become seriously sick from the new coronavirus, with breathing difficulty as one of the symptoms they’re likely to face.

With Ghana’s cases going over 1,000 with 9 deaths, issues of life-support equipment have become topical.

One of them, respirators or ventilators have been the go-to equipment for Covid-19 intensive care patients.

Sadly, the country does not have that luxury because the equipment is expensive.

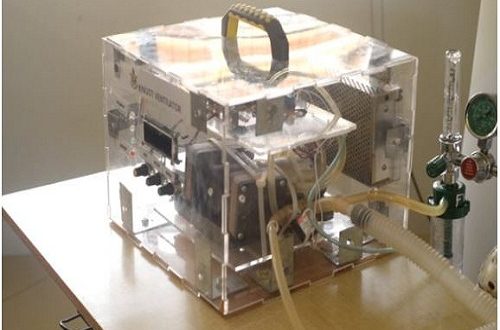

But there is hope, as engineering students at the Kwame Nkrumah University of Science and Technology (KNUST) have developed a low cost automated respirator.

In 2010, researchers led by President of the Institute for Security, Disaster and Emergency Studies, Dr. Ishmael Norman, sought to find the all-risk emergency preparedness at Ghana’s hospitals.

The study which covered all the 10 regions of Ghana found that only 45.5 per cent of hospitals had respirators or ventilators.

Students at the KNUST have, for past two years, been working on how to write a good ending to this story captured in the Ghana Medical journal.

“As a college, we observed in the year 2017 that there is a serious lack of ventilators in the country. Quite apart from Komfe Anokye and Korle-Bu Teaching Hospital, most of the district hospitals lack ventilators. So we initiated a project with the University of Michigan to build a locally-made ventilator,” provost of the college, Prof. Mark Adom-Asamoah, explains the objective of the project.

Hospital-grade ventilator costs between130, 000 cedis and 300, 000 cedis.

The team put together by Prof. Mark Adom-Asamoah has been thinking of less expensive ventilators.

“We felt if we could develop a ventilator which could have a basic function for human breathing, then it could go a long way to help our health delivery system. They came up with the first prototype and it’s been undergoing development for the past two years,” he noted.

“When issues of Covid-19 came up, we felt it’s an opportunity to ramp up the project,” he added.

The prototype has an initial cost of 20,000 cedis, which the college believes will reduce significantly, if mass-produced.

“When you’re building prototypes it’s not what we use to price the product on the market but rather all these problems we’re going through, by the time we’re done we would have produced a template to make production cheaper,” said one of the project coordinators, Prof. Kwame Osei Boateng.

Ashanti Regional Clinical Engineering Manager, Ghana Health Services, Eric Sackey Mensah though is impressed with what is likely to be the first automated ventilator to make its way into Ghana’s intensive care wards, he notes, additional functionalities will be apt.

“For a life-support unit, we need to know the amount of oxygen in the patient, something we call tidal waves, we need to record temperature and stuff like ECG,” he pointed out.

Prof. Osei Boateng has, therefore, been taking notes.

“Some people may not be in so critical condition, so at the time they’ll start regaining their composure and are able to breath, the machine will be able to sense and stop; also if their conditions get worse, the machine can start. In addition to this, we’re adding devices that can monitor signals from the body like the Electrocardiograph,” he’s optimistic.

Prof. Adom-Asamoah says the ventilator which is 95 per cent complete will be fully functional in two months’ time, but will require financial support.

Home Of Ghana News Ghana News, Entertainment And More

Home Of Ghana News Ghana News, Entertainment And More